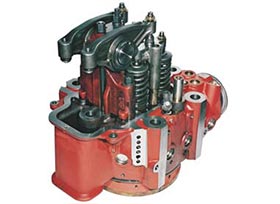

Power Source Machine is well experienced in rebuilding engine valves and manufacturing all makes and sizes for customers throughout the globe. Our extensive stock of materials allows us to supply and design with guaranteed specifications to satisfy any customer's demands. We offer cost efficient solutions both intake and exhaust valves forged and hot extrusion in a broad range of materials. The rebuilding process is just as meticulous using stellite on seat and tips areas. chrome plating on the stem. Nitriding/tuftriding